Name

Ankit Chaudhary

director@recyvoltbattery.com

phone

+91-9899417898

Address

Plot No. 17 & 18, Anand Industrial Estate, Mohan Nagar, Ghaziabad, Uttar Pradesh 201007

The electronic automobile market is increasing at a rapid pace in the whole world and especially in India. The government is encouraging various companies to start producing Lithium-ion batteries, the heart of Electric Cars and Vehicles, in India.

At Recyvolt, we look forward to guide the companies that have plans to enter into the manufacturing and recycling of Lithium-ion batteries. We look forward to support the company to set up a lithium-ion plant and train its employees as well.

The success of EVs hinges on three main factors: the carbon intensity of the manufacturing process, the carbon intensity of the electricity used to charge the battery as the vehicle is used, and what happens to the battery at the end of its useful “first” life. So recycling has a major purpose. Just don’t let this opportunity slip away and seek guidance to invest in green technology like lithium-ion, which will be in great demand in the near future.

This introduces you to the most effective ways and highly useful tools of designing, simulations, and testing of designs of EV products and components. Simulation engineering plays a key role in ensuring the success of EV products. This covers core specializations in EV technology: Battery Design, EV System Design, Simulation, and is ideal for both engineers and non-engineers who want to enter the EV industry.

It aims to impart evolving concepts in EV technology and equips attendees with skills to design, model, analyze, and test the functionality of components and entire systems. The modules include Electric Vehicle Technology and Operation, Electric Vehicle Battery Design, Electric Vehicle PowerTrain Design.

The Electric Vehicle (EV) Industry Is Paving The Way For The Future Of Mobility. The Industry Is Emerging From A Nascent Stage And Is Set To Become A Mainstream Sector. Business and Job Opportunities Are There In All Functions: R&D, Design, Simulation And Analysis, CAM, Maintenance, And So On.

EV Recycling company to save environment

Spent batteries are currently treated as waste and not as a valuable domestic resource

EV Recycling company to save environment

India does not have adequate legislations; we are providing consulting to shape up the requirements

90% recycling of consumer electronics, EVs and grid storage batteries by 2030 Federal policies requires recycled materials in cell manufacturing by 2030

Required recovery rates of +80% on battery metals in effect since 2018 Set to increase required rates to +90% on Nickel, Cobalt, and Manganese

Batteries Directive mandates that all collected batteries must be recycled, Set to increase minimum recycling efficiency rate to +75% in 2022

RECYVOLT is securing Funding from India Govt.

RECYVOLT is securing Funding from India Govt.

$+60B spent to support EV industry, including R&D for battery recycling

$1.1B Battery Alliance project to boost battery R&D

More batteries means more waste and EV batteries are notoriously hard to recycle, posing an issue once these vehicles have reached the end of their lifecycle. Currently, once a battery reaches the end of its service life, it is collected, dismantled, and shredded. The material left behind from this process is called black mass. The composition of Black Mass can vary, but it always contains elements which can be repurposed in the production of new batteries in support of a circular economy. India is at the forefront of lithium-ion battery recycling and their government is keen to build on this.

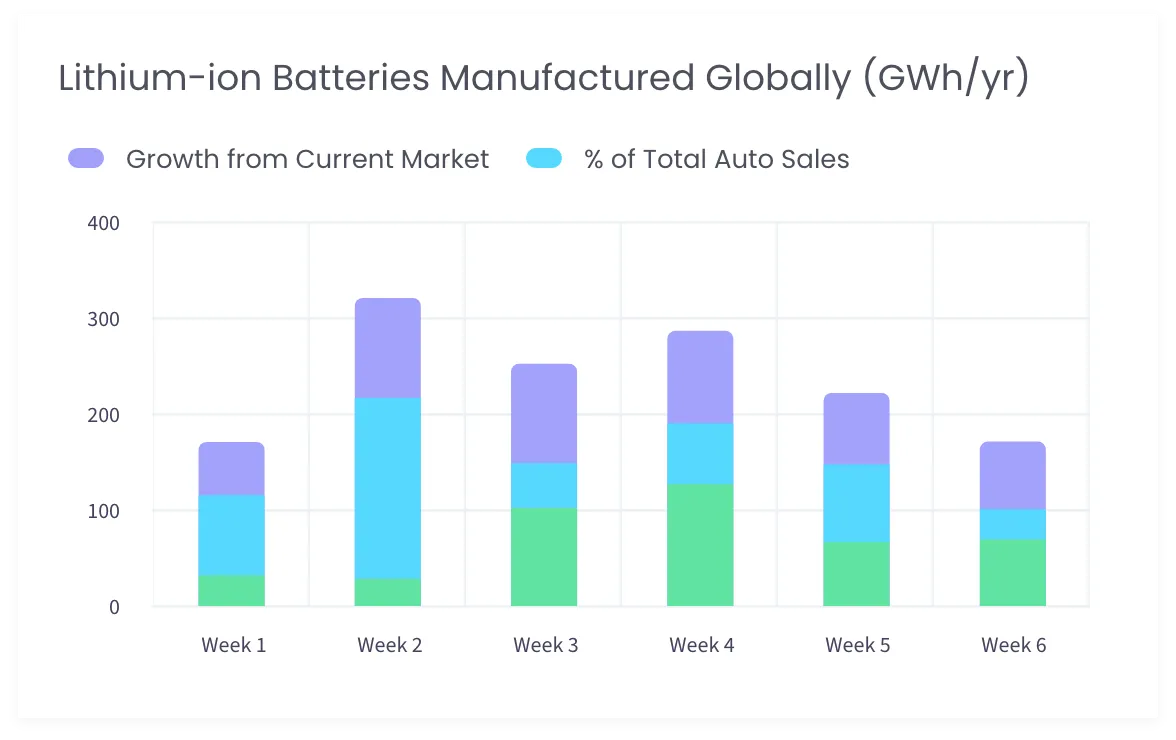

Total tonnage of lithium-ion batteries available for recycling worldwide is set to increase 500% to over, 1.2 million tonnes from 2020 to 2030

The largest segment of lithium-ion batteries that will be available in the next decade are within the EV and transportation verticals

RECYVOLT’s goal is to capture feedstock with exclusive offtake agreements and partnerships with battery aggregators in order to fill our feedstock capacity

Spent batteries are currently treated as waste and not as a valuable domestic resource

The majority of batteries currently “recycled” in the United States are

to China, Korea & Japan

The majority of batteries currently “recycled” globally are

in blast furnaces

Every battery exported to China exacerbates the Domestic India

supply problem

EV Recycling company to save environment

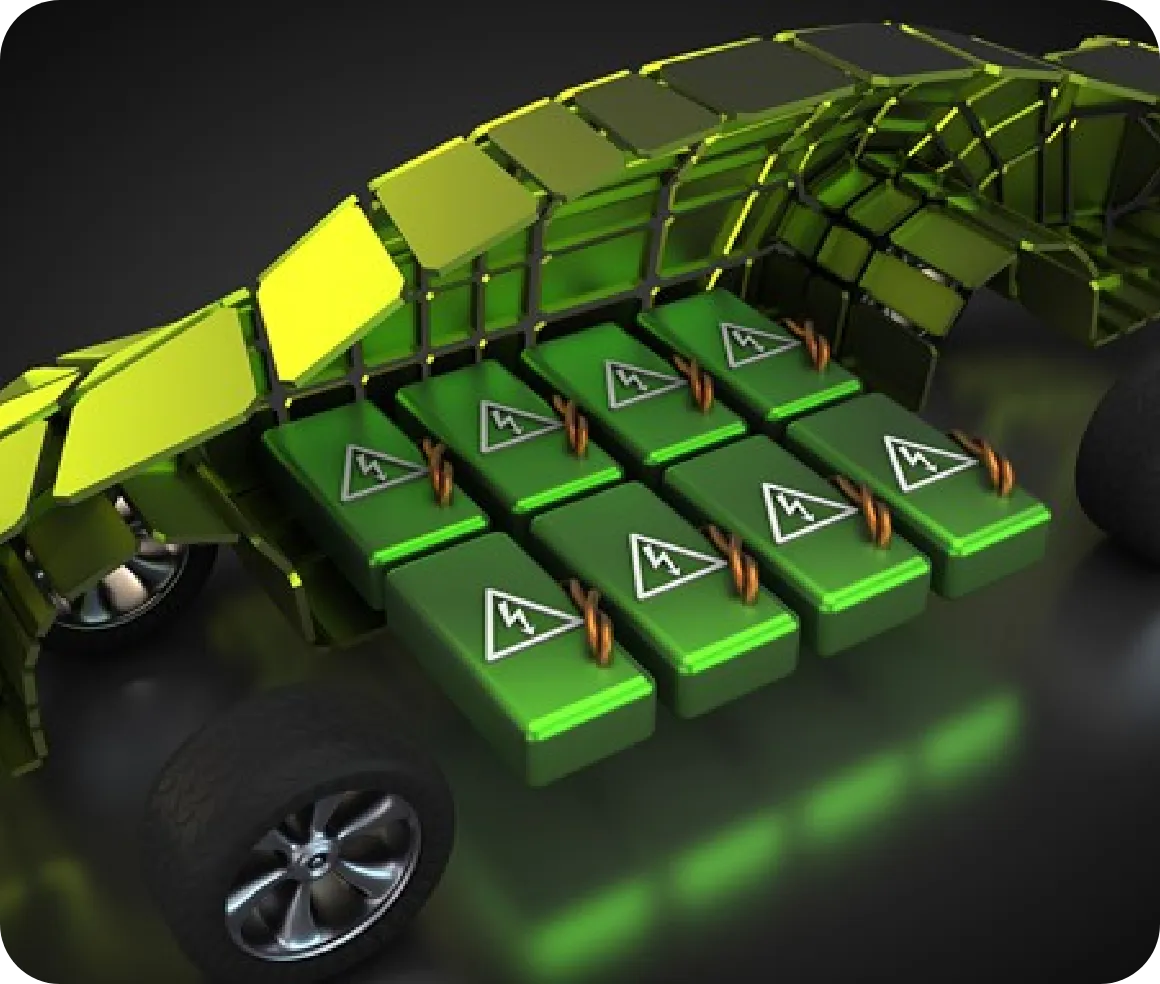

| Process |

|

|

|

|

| Description |

Breakdown of integrated modules into cells by targeting weak points |

Automated separation of individual cells, agnostic to form factor |

Material separation of battery-grade feedstock from slurry |

Synthesis of battery- grade materials to be sent out to customers |

| Output |

Al / Plastic |

Al / Fe / Steel Scrap Al & Cu Foil |

Intermediate Product Li / Ni / Co / Mn |

Battery-Grade LiOH / Ni/Co/Mn-SO4 |

| Advantage |

Strategic De- Manufacturing |

Agnostic to cell chemistry or structure |

High removal of low- value byproducts |

No hazardous waste Zero liquid discharge |